BAR TOWEL

To view the product price and make a purchase, please login to your account

Radio Frequency Identification ( RFID ) tags are now becoming a necessary tool for the modern world. RFID tags use intelligent barcodes to identify items by transmitting data from the tag to the reader. This data may include information like size, weight, color, location, chemical use, personal information, and customer. Manual inventory counts are prone to error which leads to inaccuracies, lower employee productivity, and dissatisfied customers concerning lost or stolen textiles. RFID tracks inventory with amazing accuracy reducing theft, lost linen, employee productivity, and customer satisfaction. We offer a large range of RFID tags to fit a variety of needs. From washable tags, sterilization compatible tags, textile tracking tags, garment tags, and tags for rubber applications. SimTraxx is dedicated to helping the textile industry run more efficient saving time and money and increasing overall customer satisfaction.

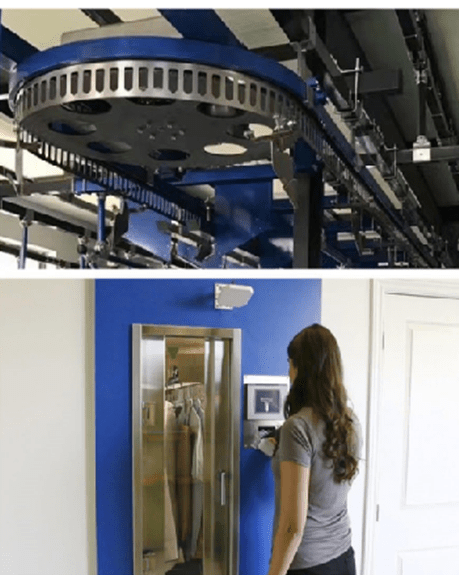

CLEAN SCAN & LABELING

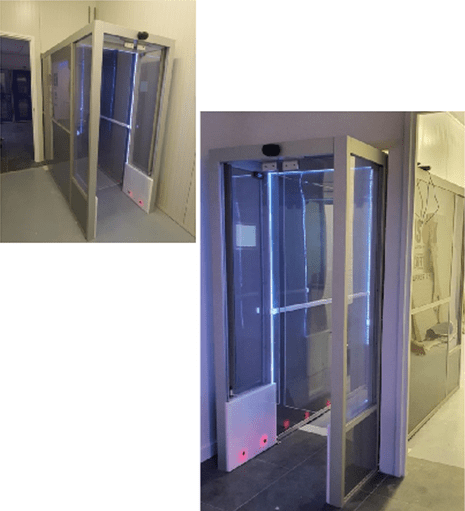

UPASS 266 is the revolutionary UHF RFID reader terminal that provides fast, unaided garment checkout on the go.

UNIFORM DISTRIBUTION TO STAFF

To view the product price and make a purchase, please login to your account

To view the product price and make a purchase, please login to your account

To view the product price and make a purchase, please login to your account

Copyright © 2024 Simtraxx – All Rights Reserved.